An advantage of being back in civilisation is I get to go to IBD meetings. The latest one at HQ was on "Laboratories in the small brewery". Marilyn Seedhouse gave a detailed, if rather rushed, talk on brewing microbiology, and Lee Walsh of QCL touted his "

BeerLab Analyser".

As the microbiology covered a lot in a short time here's the slides (well, most of them) with my comments.

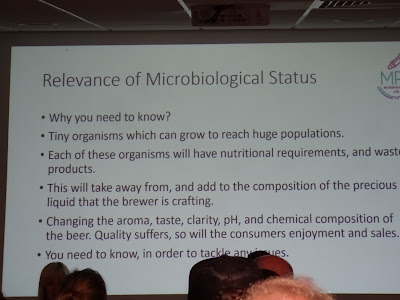

I think we're clear here that microbial contamination is a bad thing for beer.

Ah,

Bergey's Manual. That takes me back. Microorganism have names based on latin or greek and I never studied either. They can be awkward don't be intimidated and just press on doing your best. If it's any consolation apparently the latin or greek is often bad.

There are good points here like brewing there are a lot of steps involved in microbiological investigations. And also like brewing they can seem complicated at first but get much easier with practice.

Aseptic technique and

using a microscope might take some getting used to but it's worth it.

This is pretty minimal and you can even get useful results with less. I've seen small labs actually using a pressure cooker as an autoclave and you can incubate cultures at room temperature if needs be.

It seems a bit steep to have to fork out for methods, but if you can get help from someone they'll probably be happy to let you copy theirs.

The important thing is make sure you sample is not contaminated by anything else, or you results will be useless.

You can use 70% methylated spirits (70% actually works better than higher concentrations). Sadly HMRC don't seem keen on people using ethanol as a disinfectant nowadays.

We were shown how to take sample from a sample tap by spraying on alcohol and flaming first.

And how to use a

long handled sample pot.

As well as how to sample though a rubber diaphragm (which are sometimes found for example on pipes).

Once the wort has cooled it becomes susceptible to microbial contamination, so samples need to be taken from the paraflow onwards.

Methylene blue staining can be used to determine the viability of yeast, but microscopy of yeast samples is of limited use for detecting contamination. With practice you can spot contaminants but it's not the most sensitive method.

Acid washing works wonders for getting rid of bacterial contamination, but won't help with wild yeast infection. Yeast academics tend to rail against the harm it does to your pitching yeast though this may be strain dependent and I've used it successfully in the past. After acid washing the yeast should be pitched immediately.

Propagating your own yeast is a bit more involved than opening a packet and rehydrating.

Beer is actually quite inhospitable to most microorganisms.

Microorganisms are not very big and can grow quickly.

When looking for contaminating microorganisms just looking to see what grows is not very useful as in a brewery what you'll mostly grow is the pitching yeast. So selective culture media which suppress the growth of unwanted organisms (in this case generally brewing yeast) and encourage the growth of the contaminants are used. The suppression can come from adding things like cycloheximide (which will kill yeasts) or having limited nutrients available which only some organisms can use. The encouragement can come from optimising the nutrients for the organism you are interested in and providing optimal growth conditions (e.g. in an anaerobic environment provided by a

gas jar).

You can get antifoam to add to culture media if bubbles are a problem.

Most types of culture media can be bought pre-prepared in dry form from companies like Oxoid.

Some more details of culture media used in brewery laboratories.

You can buy disposable plastic spreaders too.

Other methods are also available. Membrane filtration is particularly useful when looking for low numbers of organisms in liquid, and she also mentioned that if looking for contamination in gas the gas can be bubbled though saline and the saline then membrane filtered.

Reading culture plates and identifying the organisms on them does take practice, but once you've got your eye in you can often be very accurate just looking at the colonies.

Some culture media will do things like change colour with pH which can help identify organisms.

I won't go on about the BeerLab analyser as there's a report by an ex-colleague of mine

here.